INNOVATION

Germany’s Biomethane Catch-Up Runs on Modular Speed

Standardized upgrading units are helping German biogas plants reach the gas grid faster, cutting risk and accelerating biomethane growth

9 Jan 2026

In Germany’s energy transition, progress often comes wrapped in paperwork. Yet a handful of biomethane plants have recently begun injecting gas into the grid with unusual speed. Their secret is not a regulatory breakthrough, but a more modest change in engineering.

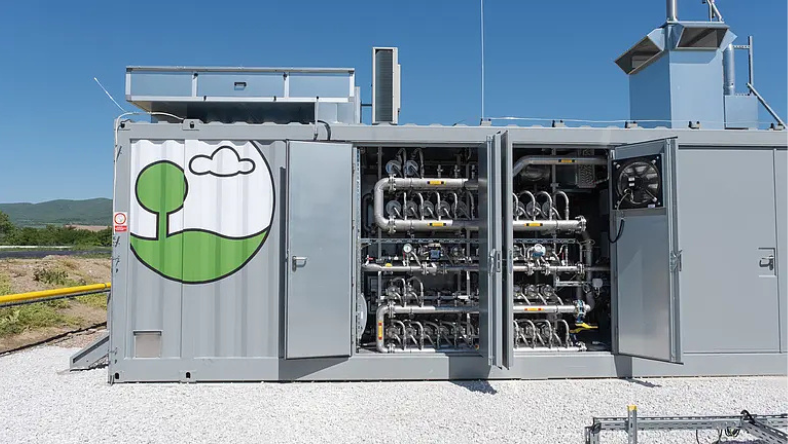

In Bavaria, Bremen and Saxony-Anhalt, several biogas facilities have installed modular upgrading units that turn raw biogas into grid-quality biomethane. Supplied by EnviTec Biogas, these systems are compact, standardised and quicker to deploy than bespoke plants. The result is fewer delays, lower upfront risk and projects that finally move from plan to operation.

That matters because most of Germany’s 9,000-odd biogas plants were built for local power and heat generation, not for feeding pipelines. Converting them has proved costly and slow. Permits take time, grid connections are complex and investors are wary of betting heavily before revenues are certain. Modular upgrades offer a way around some of these hurdles. Operators can add capacity in stages, using equipment that arrives largely pre-assembled.

The approach is still niche. Only a small number of plants have adopted it, and no one claims it has transformed the market. But it fits Germany’s current mood. Concerns about energy security since Russia’s invasion of Ukraine have kept interest in domestic gas alive, even as subsidies fluctuate and financing remains tight. The European Biogas Association has pointed to standardised solutions as a way for smaller, decentralised producers to access gas networks. One executive involved in recent projects called modular designs “a realistic path from pilot scale to commercial operation without betting everything upfront”.

The benefits ripple outward. Grid operators prefer predictable gas quality. Local communities like projects that reuse existing sites rather than build new ones. Consumers gain a slightly cleaner gas mix without changing boilers or cookers. None of this is dramatic, but it is practical.

Obstacles remain. Clearer policy, better investment conditions and spare network capacity will all shape how far biomethane can grow. Modular plants do not remove those constraints. They merely work around them. In doing so, they suggest that Germany’s renewable-gas expansion may advance less through grand strategies than through smaller, quicker steps.

Latest News

21 Jan 2026

Europe’s Biogas Plants Test a Virtual Upgrade19 Jan 2026

From Chicken Litter to Clean Energy in Ireland12 Jan 2026

Biogas Goes Big as €28B Floods Europe9 Jan 2026

Germany’s Biomethane Catch-Up Runs on Modular Speed

Related News

TECHNOLOGY

21 Jan 2026

Europe’s Biogas Plants Test a Virtual Upgrade

INSIGHTS

19 Jan 2026

From Chicken Litter to Clean Energy in Ireland

INVESTMENT

12 Jan 2026

Biogas Goes Big as €28B Floods Europe

SUBSCRIBE FOR UPDATES

By submitting, you agree to receive email communications from the event organizers, including upcoming promotions and discounted tickets, news, and access to related events.